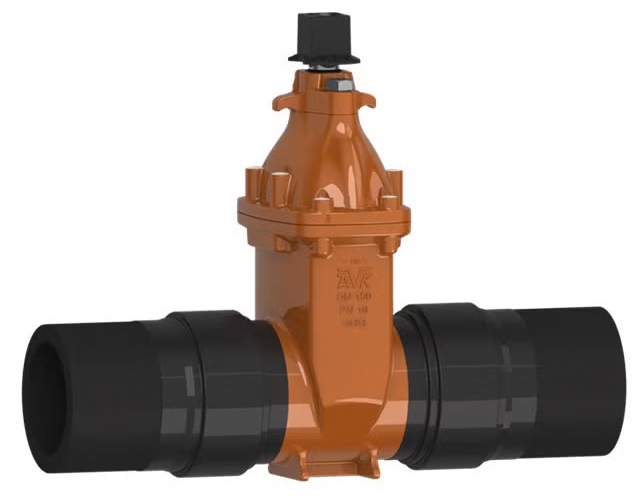

Resilient seated gate valve with HDPE ends, for drinking water and neutral liquids to max. 160°F

The American AVK Series 66 is designed especially for use in polyethylene water distribution systems. The valve is identical to our premier resilient wedge gate valve with one exception: The PE-pipe stubs are already mounted. This means lower installation costs and leak proof joints.

Features

- NEW: 2-inch and 3-inch sizes now available

- Sizes 4-inch through 12-inch available

- Hydrant bases available with PE connectors

- The patented valve to pipe joint is water-tight and high strength – stronger than the pipe itself

- Optimum corrosion protection and finish of the valve joint is ensured by the heat activated polyolefin covering meeting the requirements of AWWA C216

- Connection to all types of PE possible

- PE pipe stubs comply with AWWA C906 and are NSF 61 certified.

- The valve can be installed using socket fusion or butt welding processes – a boltless assembly means corrosion free joints

- The valve joint can resist thrust loads – eliminating the need for thrust blocking

- All AVK gate valves with PE ends meet or exceed the requirements of AWWA C515 where applicable

- Lead free

- Threads rolled in a separate cold pressing process to enhance strength

- Rolled threads ensure smooth thread edges and low operating torques

- Twice the yield strength required by AWWA eliminates bent and broken stems

- Bronze stems are available

- Packing gland bolts and bonnet bolts are stainless steel for corrosion resistance

- Bonnet bolts are countersunk and capped with hot melt to totally isolate the bolts from corrosive environments

- O-ring bonnet gasket wraps each bolt to prevent corrosion

- Bonnet blow offs due to bolt corrosion eliminated

- Ductile iron wedge fully encapsulated in EPDM rubber with an integral bronze stem nut for optimum corrosion protection and precision wedge tracking

- EPDM resists attack from chloramines

- Ductile iron gland flange for protection should the valve be over-torqued in the closed direction – will not break or crack

- Gland flange equipped with cast in lifting lugs for easy handling

- Wiper ring – to prevent impurities from entering the stem and to protect the o-rings

- Two o-ring stem seals to reduce friction and prevent wear and tear – replaceable under full pressure

- Third o-ring stem seal protects upper stem from impurities entering from the water way

- Coating to AWWA C550 – Electrostatically applied fusion bonded epoxy coating inside and outside for excellent corrosion resistance

- 100% testing – All valves tested to 250 PSI / 500 PSI as required by AWWA