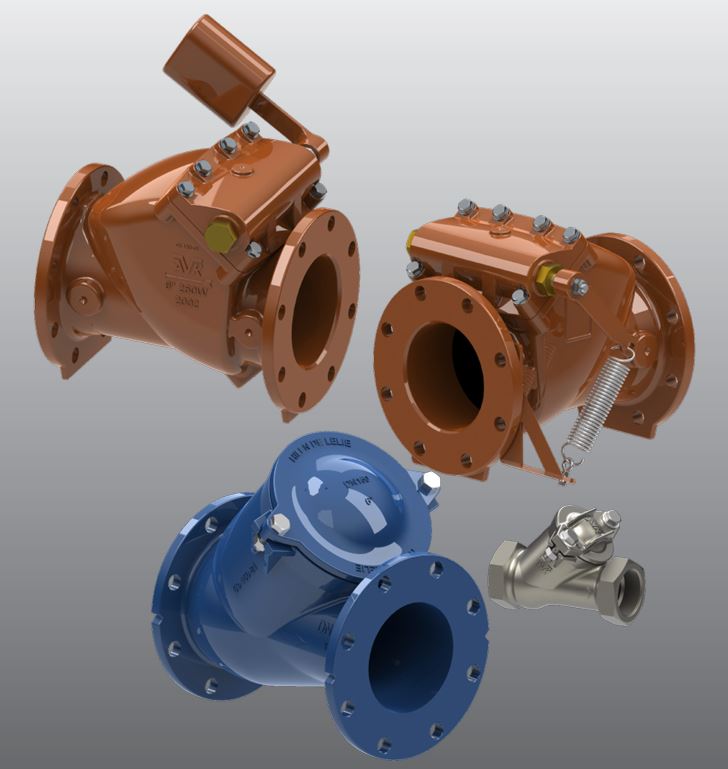

AVK offers a wide range of swing check valves featuring a clear waterway and low head loss, resulting in maximum utilization of the pump capacity. The check valves can be installed in both horizontal and vertical positions and are easy to maintain. Different options are available for prevention of water hammer.

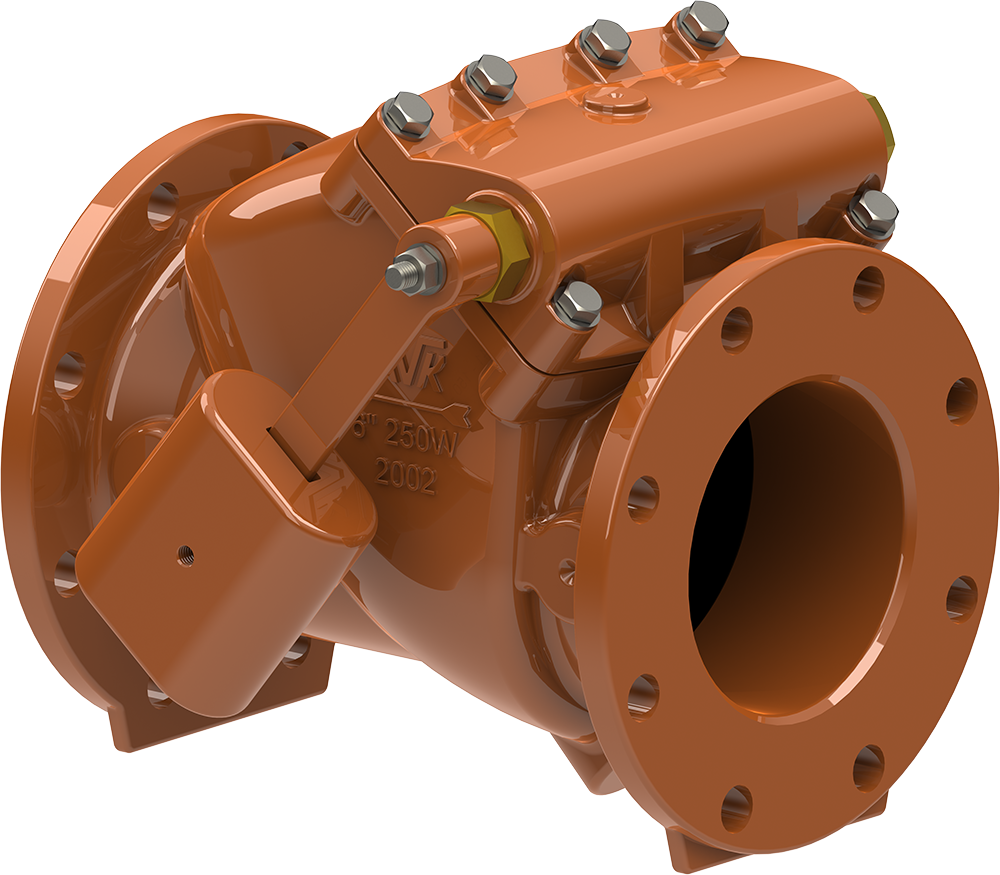

The AVK Series 41 is designed to be the easiest to maintain check valve on the market. Simply remove the bonnets bolts – bonnet, hinge, and disc can be removed as one unit, leaving the valve body inline. The valve can then be easily cleaned and any repairs can be made without having to reach into the valve. A new head assembly can be installed immediately to reduce downtime.

• Meets or exceeds AWWA C508

• Available in 3″ through 12″

• All internal exposed metal is stainless steel or fusion bonded epoxy coated

• Lightweight disc reduces inertia and assists in closing

• Reduced opening angle for faster closure

• Tested to 1,000,000 cycles; rated to 250 psi

• Easily maintained, with no need to remove valve from the line

• Steel disc is encapsulated in EPDM rubber

• Hinge, bonnet and disc are one easily removable assembly

• Interior and exterior, fusion bonded, epoxy coating comply with AWWA C550

• Hinge shaft is sealed with o-rings for long-life and easy replacement

• Stainless steel bonnet bolts are sealed by bonnet gasket

AVK offers a wide range of swing check valves featuring a clear waterway and low head loss, resulting in maximum utilization of the pump capacity. The check valves can be installed in both horizontal and vertical positions and are easy to maintain. Different options are available for prevention of water hammer.

• Flange to flange dimensions are to ANSI/ASME B16.10

• Flanged sizes available in 2″ through 24″, ductile iron

• Ductile iron and stainless steel NPT available in 1½” and 2″ sizes • Pressure rated to 150 psi

• 100% testing – All valves tested to 150 psi leak test/225 psi hydrostatic shell test

• Simple bolt-on cover for easy inspection and maintenance

• Can be mounted vertically or horizontally

• Vertical installations can have downward flow when floating ball is used

• Nitrile (NBR) and Polyurethane (PUR) balls available

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |