OPERATION AND MAINTENANCE

OPERATION

WARNING: Flush the system prior to operating valves to prevent damage to seats and plugs.

1. Do not operate the valves in a system that exceed the valves rated working pressure of 250 PSI.

2. AVK Eccentric Plug Valves are “Open Left” or counter-clockwise to open, quarter turn or 90 degrees to open or close.

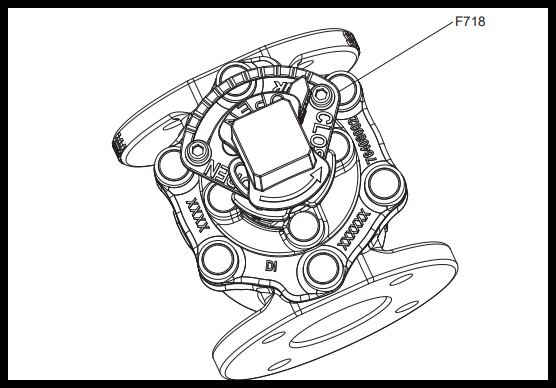

3. Manually actuated valves have mechanical stops for the open and closed positions that are clearly marked on the Stop

Plate (F718). There are also detents in the Stop Plate (F718), if valve throttling is desired. ( See Fig. 5 )

4. For valves with gearboxes, the number of turns to open and close are as follows:

2½”, 3″, and 4″ – 8.5 turns

6″ – 9.5 turns

8″ – 12 turns

10″ and 12″ – 24 turns

5. Valve operation and cycling should be scheduled more frequently for systems that have higher solid contents in the water.

6. Never force the valve to seat. Re-open the valve and flush the system again to verify that debris has been dislodged from

the seating area.

MAINTENANCE

WARNING: Flush the system prior to operating valves to prevent damage to seats and plugs. When performing

maintenance that requires disassembly on valves, ensure that the system pressure is at 0 PSI.

1. AVK Eccentric Plug Valves are designed to be relatively maintenance free. Do not disassemble valves unless an

interruption to normal service has occurred in the system.

2. Periodic lubrication is not required. Lubrication is only required if disassembly/reassembly of the valve is performed.

3. Regular functional inspections should be performed at a minimum of twice a year. When performing a functional

inspection, operate the valves under normal working pressure, making sure they operate normally without any vibrations.

4. For valves with gearboxes, refer to the gearbox manufacturer’s maintenance procedures.

5. Proper records should be maintained for all maintenance procedures and schedules.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |