MAIN VALVE INSPECTION

WARNING: For all of the following repair procedures, the hydrant must be isolated or the system depressurized and drained before removing the hydrant components. Failure to do so may cause pressure to be released resulting in severe injury or death.

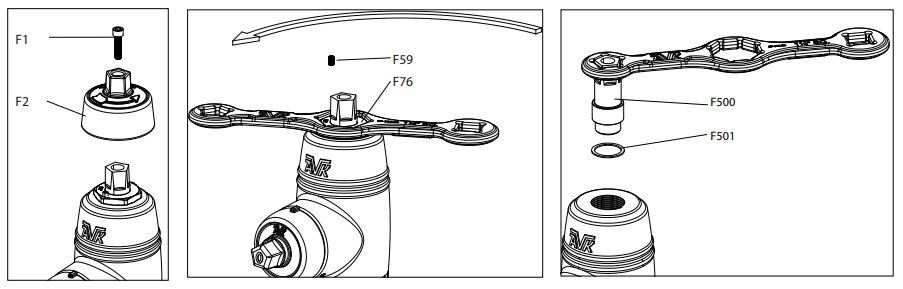

1. Check direction of opening as marked on the hydrant Weathershield (F2).

2. To Open, turn the Operating Nut (F500), in the opening direction, indicated by an arrow on the Weathershield (F2), until the

Main Valve (F518), hits the stop in the hydrant Base (F519). Do not force the hydrant in the opening direction beyond

full open as indicated by sudden resistance to turning. If water does not flow when the hydrant is open, it is probably

due to a closed valve upstream from the hydrant.

3. Remove the Weathershield (F2), by removing the Weathershield Bolt (F1), using a 5/16″ or 8mm Allen wrench.

(See Fig. 5)

4. Loosen the Thrust Nut Retaining Screw (F59), using a 5/32″ or 4mm Allen wrench. Using the AVK Series 67 hydrant

wrench, remove the Thrust Nut (F76), and Thrust Nut O-ring (F52). (See Fig. 6)

5. Using the AVK Series 67 hydrant wrench, remove the Operating Nut (F500), and Anti Friction Washer (F501).

(See Fig. 7)

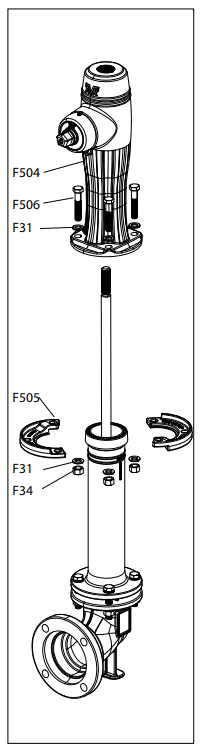

6. Using 15/16″ or 24mm wrenches, remove the Nozzle Section Bolts (F506), Washers (F31), and Nuts (F34). Set the

Two Piece Breakable Flange (F505), aside with the hardware. Lift the Nozzle Section (F504), assembly up over the

Upper Stem Rod (F503). Also remove the Flange O-ring (F73). (See Fig. 8)

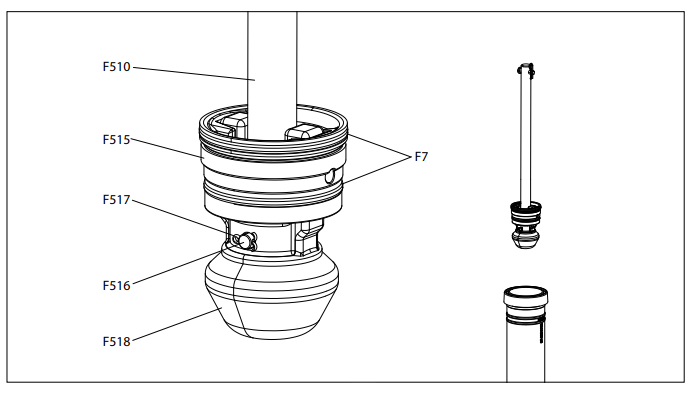

7. Remove the lower Springpin (F38), and Coupler Pin (F507), from the Lower Stem Rod (F510). Remove the Upper Stem

Rod and Breakable Coupling (F508), from the Lower Stem Rod. Re-install the Coupler Pin and Springpin on to the Lower

Stem Rod. (See Fig. 9 & Fig. 10)

8. Place the AVK Series 67 T-Wrench over the Coupler Pin and remove the Lower Stem Rod/ Main Valve assembly by

turning counter clockwise. (See Fig. 11 & Fig. 12)

9. Once removed, check the Valve Seat O-rings (F7), and Main Valve (F518), for damage. Also verify that there is no

damage to the sealing surface on the Valve Seat Ring (F515).

10. If replacement of the Main Valve (F518), is necessary, refer to the MAIN VALVE REPLACEMENT section in the REPAIR

PROCEDURES section on page 15.

NOTE: When re-installing the Thrust Nut (F76), tighten the Thrust Nut completely, then back it off 1/8 to 1/4 turn. Then tighten

the Thrust Nut Retaining Screw (F59), to lock the Thrust Nut in place.

Note: Torque the nozzle section hardware to 60 Ft. Lbs..

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |