CAUTION: With the valve in the fully “OPEN” position, the

following procedures can be performed under full working

pressure, with no need to shut down the system.

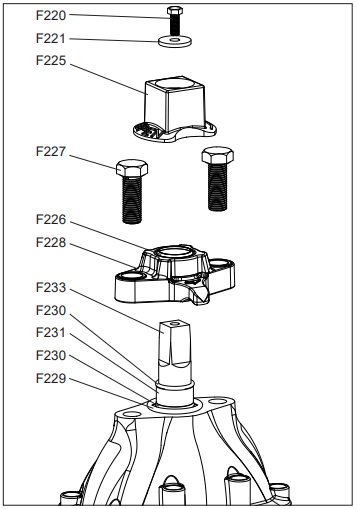

1. Remove the Wrench Nut/ Handwheel Bolt (F220) and

Wrench Nut/Handwheel Washer (F221) using a 1/2”, (13mm)

wrench, for 2 1/2” to 4” valve sizes, and 11/16”, (17mm)

wrench for 6” to 12” valve sizes. Remove the Wrench Nut

(F225) or NRS Handwheel (F222). (See Fig.4)

2. Remove the two Gland Flange Bolts (F227) using a 15/16″ or

24mm wrench for valve sizes 2.5″-4″, or a 1 1/4″ or 30mm

wrench for valve sizes 6″-12″.

3. Remove the Gland Flange (F228) with Wiper Ring (F226)

attached.

NOTE: The Wiper Ring (F226) is a “Factory Installed” press fit

and therefore must be reordered as an assembly along

with the Gland Flange (F228).

4. When performing step 3, verify the location of the Upper

Stem Seal O-rings, quantity 2, (F230) and the Stem Seal

Bushing (F231). They may be located on the Stem (F233),

(See Fig. 4A), or in the counterbore of the Gland Flange

(F228), (See Fig. 4B).

5. There is a groove in the bottom of the Gland Flange (F228),

for the Gland O-ring (F229). (See Fig. 4B)

6. Inspect and replace any damaged parts. Use a food grade

grease that contains no acetate or silicone, on the o-rings.

Re-assemble in reverse order.

WARNING: To perform the following steps, be sure the Water

Main Supply Line has been shut off, and that the pressure has

been bled off! Also provide sufficient clearing around the valve

so that no soil or debris may fall into it.

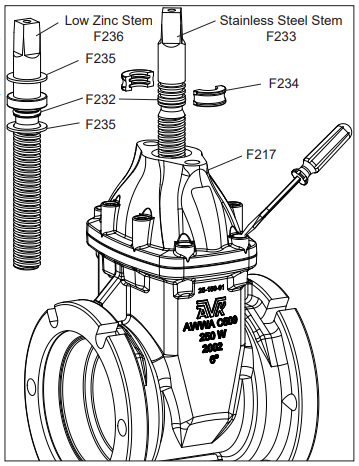

1. Complete steps 1 through 4 in the UPPER STEM SEAL

COMPONENT REPAIR section.

2. Turn the Stem (F333), in a closing direction until it

disengages from the Wedge (F237), and remove from valve.

3. If applicable, for Low Zinc Stems, remove the Lower Anti-

Friction Washer (F235) from the recess in the bonnet (F217).

For Stainless Steel Stems, the Stem Collar and Anti-Friction

Washers are replaced by a two-piece Thrust Collar (F234).

No Anti- Friction are necessary or present. The Lower Stem

Seal O-ring (F232) should be present on the stem and in it’s

own groove, located directly above the threads.

NOTE: On Stainless Steel Stems, the upper three grooves are

for locating the Thrust Collar.

4. Inspect and replace any damaged parts.

NOTE: Use a food grade grease that contains no acetate or

silicone on the new o-rings.

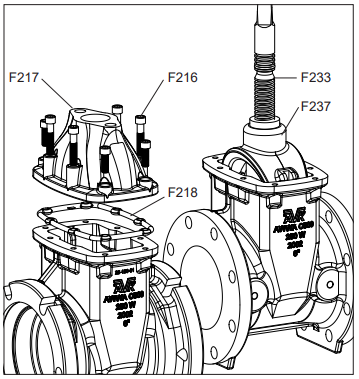

5. Using a small, flat bladed screwdriver, remove the hot melt

glue that covers the Bonnet Bolts (F216).

6. Once the hot melt glue has been removed, use a 3/8”, or

10mm Allen wrench to remove the Bonnet Bolts (F216).

Remove the Bonnet (F217) and Bonnet Gasket (F218) and

set aside.

7. To remove the Wedge (F237) it is sometimes helpful to

thread the Stem (F233) back into the wedge and use the

stem as a handle or lever to extract the wedge. This is

helpful with the larger sizes, (10” and 12”) valves.

8. Carefully inspect the interior of the valve body and remove

any debris.

9. Inspect and replace any damaged parts and re-assemble in

reverse order, torquing the Bonnet Bolts to 40 ft. lbs., in a

diametrically opposed (180 degrees apart) pattern.

9. To replace the protective hot melt glue over the Bonnet Bolts,

use any EPA approved caulk, or hot melt glue

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |